Matching colours accurately is extremely important when it comes to corporate branding, so screen printing is perfect for logos and other branded merchandise. Because the inks are mixed for each print job, if you have a specific pantone in mind, the ink mixer can match to that pantone. If you need to pantone match to your branding or certain colours, then screen printing is the option to choose. However, you have vibrant colours and clean lines in your design, DTG is no match for screen printing,

#Silkscreen printing is skin#

When it comes to gradients with smooth transitions, details such as fine lines, skin tones, digital printing is much more reliable than screen printing. Is your design one colour, or a gradient? Does it include lots of intricate patterns or detailed drawings? If it is a photograph or has photographic detail, DTG printing is the best choice. Screen printing on the other hand can print on any colours and any fabrics from cotton, blends, polyester, denim, performance fabrics, and more. What type or product do you want to print on? Is constructed from a man-made fibre or natural cotton? DTG is limited in this area because it is recommended to only print onto 100% cotton- it will struggle with 50/50 blends, polyester, and technical fabrics such as nylon.ĭyed fabrics can also cause problems for DTG due to dye migration, this is when the garment dye bleeds into the ink and causes discolouration. If you need a large order, screen printing is the better option as the set-up cost is spread over the larger quantity. DTG printing doesn’t cost that much set up, which means that it is a more cost-effective option for printing small batches or single items.

What to consider?Ĭhoosing which print technique to use is dependent on a few different factors.ĭepending on if you need 1 or 200 bags, one print method may be more cost effective. The printer uses CMYK ink which gives a much wider range of colours than other ink systems. The garment is then heat pressed to seal the print onto the fabric. Digital printingĭigital printing is a fairly modern technique, the ink is printed directly on to the fabric in the same way an inkjet printer prints onto paper.

Ink is mixed for each print job, so the ink colour is mixed just for you, so this means that pantone colour matching is possible.

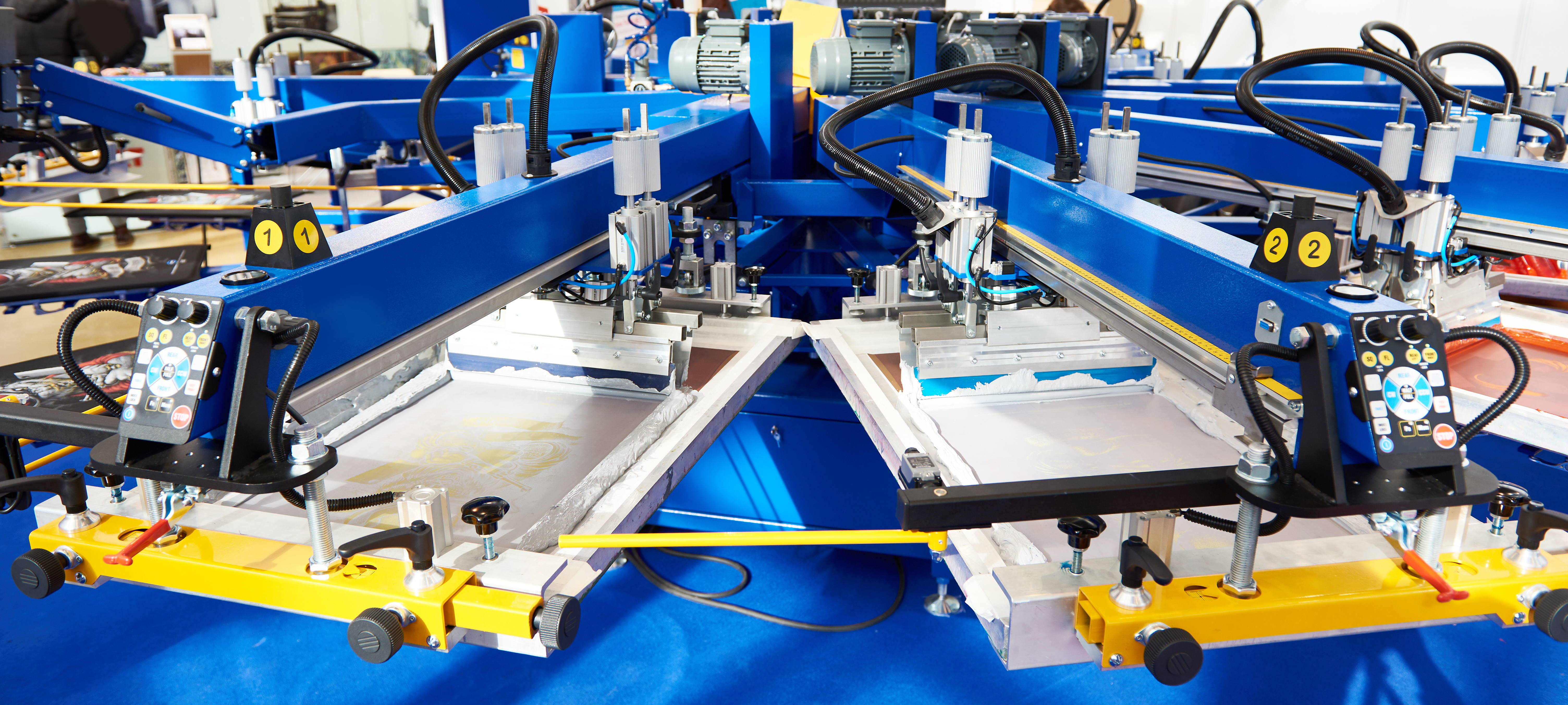

Screen printing is when ink is pushed through a stencilled mesh screen, which has been placed above a garment, which creates a printed design.Ī separate stencil is made from each colour of the image, the ink is pushed through each stencil to build up the whole final design with all the colours. Screen printing also known as silk screen printing or serigraphy is a traditional print technique which has been around for centuries. Both have their uses and this guide will give you an overview of the techniques, the advantages, and disadvantages of both, when to use them, and why. The two most common forms of garment printing are screen printing and digital printing. With the amount of garment printing techniques that have been developed, it can be confusing to understand the difference between them, and when best to use them.

0 kommentar(er)

0 kommentar(er)